TURBIDIMETER

About

The equipment is used for continuous culture of various microorganisms (E. coli, yeast, etc.), antibiotic screening and continuous evolution experiments. During operation, chemostat mode (constant flow rate) and turbidimeter mode (constant cell concentration) can be selected. When the equipment operates in the turbidimeter mode, the instrument adjusts the flow rate by reading the cell concentration in real time to keep the cell concentration constant. When reaching the steady state, the cell concentration is the set target concentration. The cell growth rate and steady-state environment depend on the set cell concentration, and the growth rate can be calculated by pump speed. It can realize the steady-state culture of the maximum growth rate of cells. When the cell concentration is very low, the cell consumption of environmental substances can be ignored, and the environment is the given environment. The turbidimeter is suitable for steady-state quantitative measurement in various given environments.

Product features:

Fully automated. The modes of turbidimeter and chemostat can be freely selected. Multi channel parallel (generally 8 channels, the number of channels can be customized), and each channel is controlled independently. The rotor speed in the channel is adjustable. Real time reading / storage of cell concentration and pump speed (time resolution up to 1s). Target cell concentration and pump speed can be set in real time.

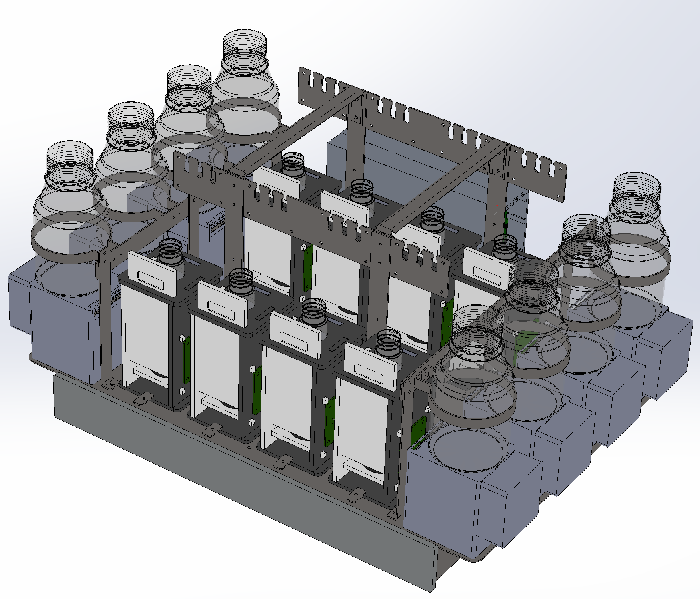

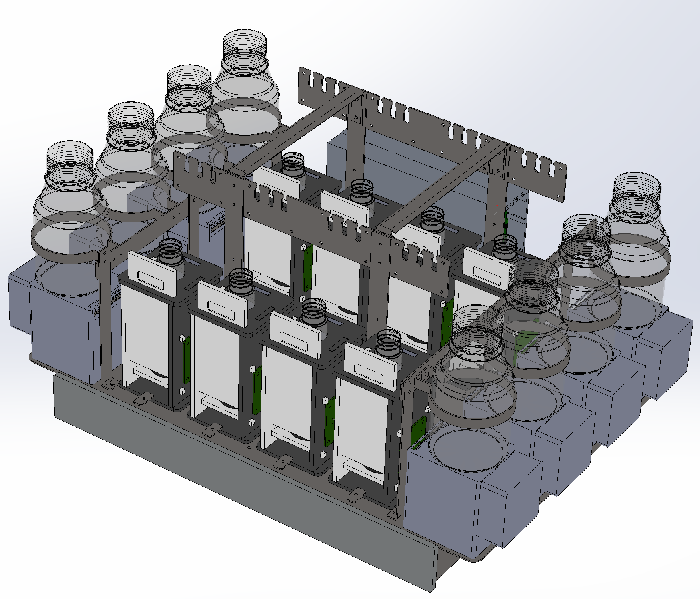

Product composition

The equipment is mainly composed of the following parts:

Peristaltic pump

Magnetic stirrer

Turbidity measurement devices

Data acquisition card

Product connection

First, confirm that the power switch button of the turbidimer (located in front of the right board of the turbidimer) is off (off Pop-Up).

Then, connect the DC output of the power line of the DC regulated power supply and the 4-core aviation plug of the 485 communication control line to the power input socket of the turbidimer (located behind the right board of the turbidimer) and tighten the fixing screw.

Thirdly, insert the USB cable for data acquisition into any USB port of the control computer (the first use will prompt the discovery of new hardware, please install the driver according to the Ni daqmx installation section in the software installation section), Insert the USB cable of the 485 communication controller into another USB port of the control computer (the first use will prompt the discovery of new hardware. Please install the driver according to the 485 serial driver installation section of the software installation session).

Finally, after confirming that the connection is correct, turn on the power switch of the equipment. At this time, software can be used to control the operation of the equipment.

Installation and configuration of control softerware

Operating environment requirements

Hardware requirements:

CPU: intel i3 or more

Memory: 2G or more

USB port: 2 or more

OS:

Windows 10/7 SP12

software environment:

Install Microsoft VC + + runtime and Microsoft Excel 2007 or above.

Installation of driver

The software uses USB to control the equipment for data acquisition and USB serial port to control the peristaltic pump speed of the equipment. Before running the software, the driver of the above hardware equipment needs to be installed.

485 serial drive installation

Unzip the zip package CDM V2 12.28 WHQL Certified provided by the equipment. Connect the 485 controller to the USB port of the computer through the USB cable, and open the device manager of windows system. Other devices with yellow warning symbol will appear in the device manager; Ttl232r device as shown in the figure below. Right click ttl232r under other devices, as shown in the following figure. Select the update driver software option in the pop-up menu, and select the manual search driver software option in the pop-up page. Select the folder to which the driver has been compressed, click next, and then start installing the device driver. When the installation is completed, a successful installation page will pop up. Click close to return to the device manager interface. If other devices with yellow warning signs are found, it is because the driver at the bus level of the converter has been installed and the driver at the single virtual serial port level has not been installed. Install again according to the above steps. After the final installation, a new USB serial port (USB serial port (COM3)) will be added in the port item (ports (COM & LPT)) of the device manager. This port is the peristaltic pump communication port of the control software. Enter the number (3) of this serial port in the peristaltic pump port of the control software.

Installation of NI-DAQmx

decompress the zip package of ni daq1810f1 provided by the equipment. Enter the extracted directory and click setup Exe to install Ni daqmx. Follow the prompts and install according to the typical configuration. After installation, insert the USB of the data acquisition card into the USB port of the computer, and the system will automatically install the device driver. If the find new hardware wizard appears, follow the wizard to automatically install software for your device. Start the Ni MAX software, click the device and interface, and the Ni DAQ device used on the computer will appear, as shown in the figure below. The data acquisition of the device is Ni usb-6008 device, and the "dev1" behind it is the device number of the acquisition card. This section needs to be input into the [DAQ] setting option of the configuration file. See the description of the configuration file of the turbidimer for details.

京公网安备 11010802035070号

京公网安备 11010802035070号